Recently, our company received feedback from customers on the application of the YX-G168 model in the Majnun oilfield project in Iraq. The customer feedback said that the equipment was highly recognized by the construction party after it was applied on site. The following will briefly introduce the application of the device:

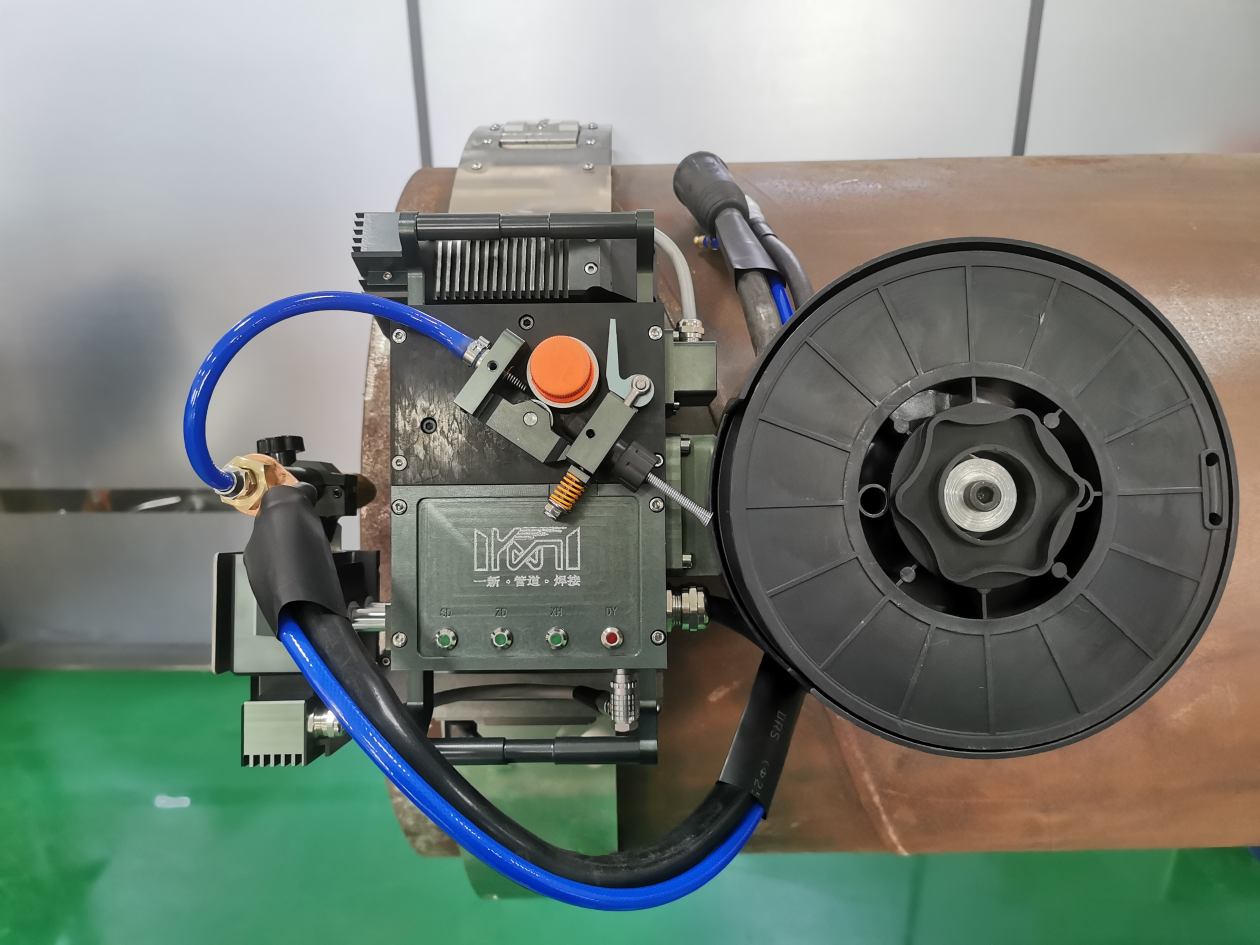

Equipment model: YX-G168 automatic pipeline single torch external welding machine (also known as pipeline external welding machine, pipeline automatic welding equipment, on-site pipeline automatic welding equipment, orbital automatic welding machine, pipeline automatic welding machine, automatic pipeline welding machine, carbon steel pipe automatic welding equipment, water pipe automatic welding machine, pipe installation automatic welding machine, stainless steel pipe welding equipment).

On-site welding process: hand argon arc bottoming (GTAW process) + automatic single-gun external welding machine automatic filling (FCAW-GS process).

Equipment application: According to on-site feedback, the equipment welding process has a high degree of automation, minimal human intervention, high weld consistency, beautiful shape, and a radiographic inspection pass rate of over 98%. The specific characteristics are as follows:

1. The welding head has a fine design, is small and portable, and has high welding precision with customized rail applications.

2. High-definition touch-screen wireless remote control operation, parameter presets can be performed to realize automatic welding, and smooth transition of welding can be achieved through multi-angle partitions to ensure high-quality welding seams at all angles.

3. The operation is simple, the basic welder can operate, and realize the fish scale welding.

4. The function of linear oscillation and pendular oscillation can be switched freely, which can realize welding of various wall thicknesses and groove types, and is suitable for a wide range of applications.

5. Integrated storage device, the whole set of equipment can be integrated into the power box, and the universal wheel is installed, which is suitable for the transfer between various projects and facilitates on-site management.

Post time: Sep-21-2022