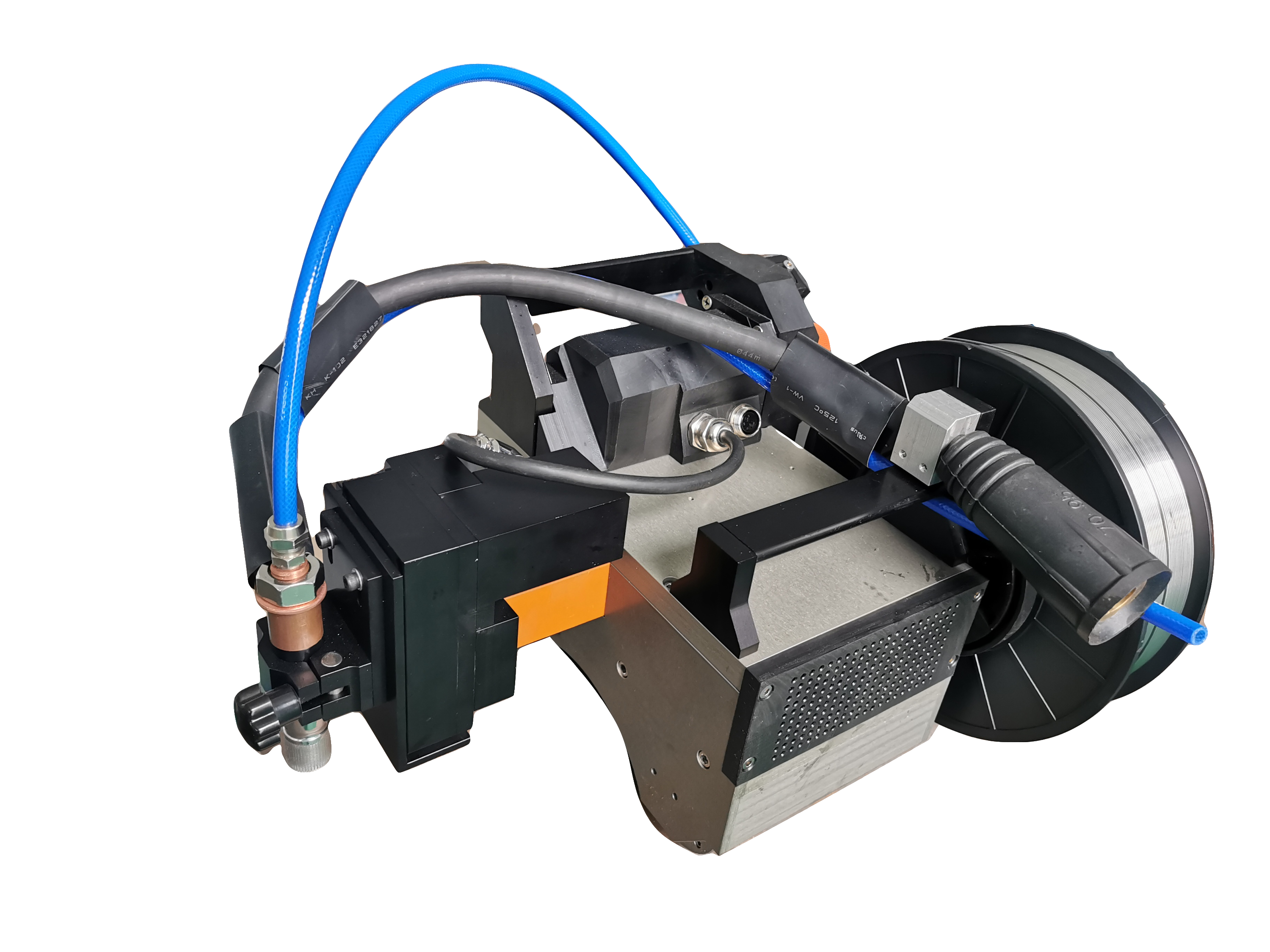

Factory supplied China Automatic welding head for carbon steel pipe welding

Equipment working mode:

The welding head is magnetically attached to the pipeline. Through preset parameters, the hand-held remote control can fine-tune the welding parameters to control the automatic welding of the welding trolley on the pipeline.

Features:

The pipe is fixed and the welding trolley travels to realize automatic welding (5G welding) in all positions of the pipeline. The welding process adopts high-efficiency and low-cost carbon dioxide gas or mixed gas protection. (80% argon + 20% carbon dioxide).

Performance advantages:

Applicable working conditions: on-site welding of various long-distance pipelines, thermal pipelines, buried pipelines or process pipelines.

Welding material: carbon steel, stainless steel, alloy steel, low temperature steel, etc.

Applicable welds: pipes with diameters above Φ114mm and wall thicknesses greater than 5mm can be applied. Thick-walled pipes can be welded in multiple layers and multiple passes.

Welding trolley: The design is light and easy to carry, and it adopts permanent magnet adsorption, which is especially suitable for all-position welding of pipelines on the construction site.

Wireless remote control: The welding parameters can be preset by wireless remote control, which can be fine-tuned in real time according to the working conditions during welding. The operation is simple and the labor intensity is low.

Welding efficiency: fast speed, high production efficiency, and can be increased by about 3-4 times compared with manual arc welding.

Welding quality: Welding seam is beautifully formed, without porosity, slag inclusion, unfusion, etc., and the welding quality is good. The pass rate of second-level radiographic inspection is over 97%, and the pass rate of ultrasonic inspection is close to 100%. Meet the requirements of pressure test or impact, tensile, bending and other mechanical properties inspection.

Weldable styles: pipe-pipe circumferential seam internal and external welding, pipe-elbow, pipe-flange, horizontal and vertical welding of tanks, horizontal welding of pipe piles, etc.

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Factory supplied China Automatic welding head for carbon steel pipe welding, We sincerely hope to determine some satisfactory interactions with you in the in the vicinity of long term. We'll hold you informed of our progress and stay up for building steady small business relations along with you.

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for automatic welding head, high efficiency welding head, We're in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.