OEM manufacturer Welding Source - Closed Type Small Pipe Welding Machine – Yixin

OEM manufacturer Welding Source - Closed Type Small Pipe Welding Machine – Yixin Detail:

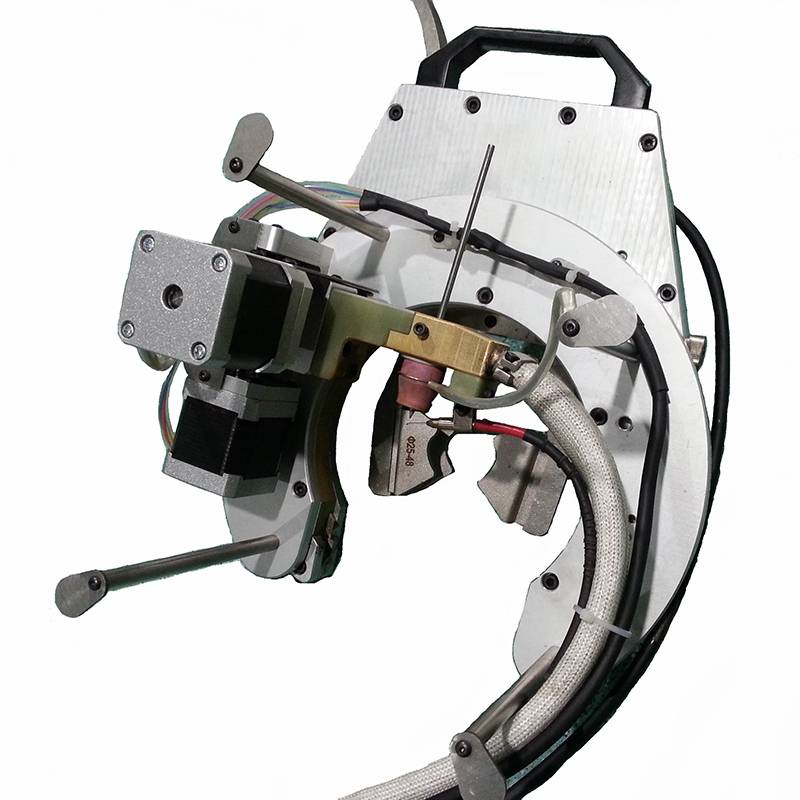

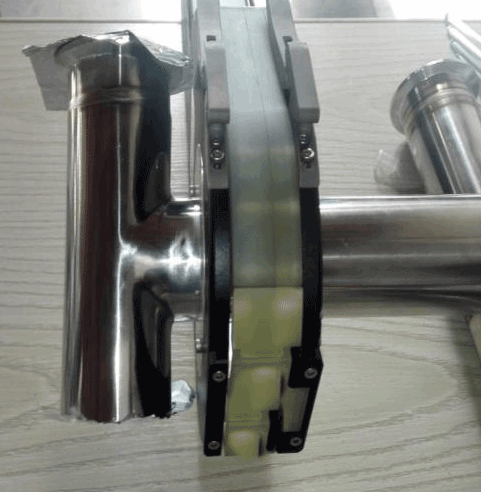

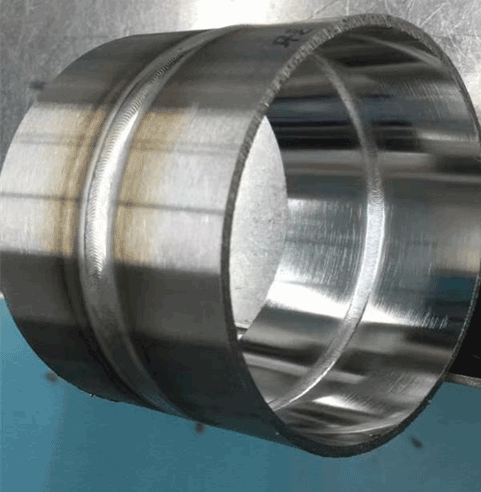

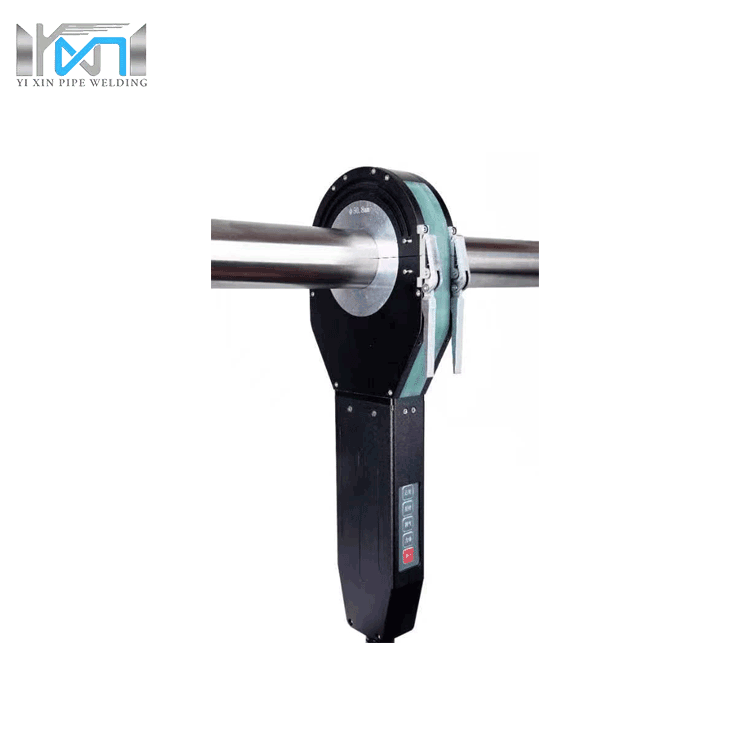

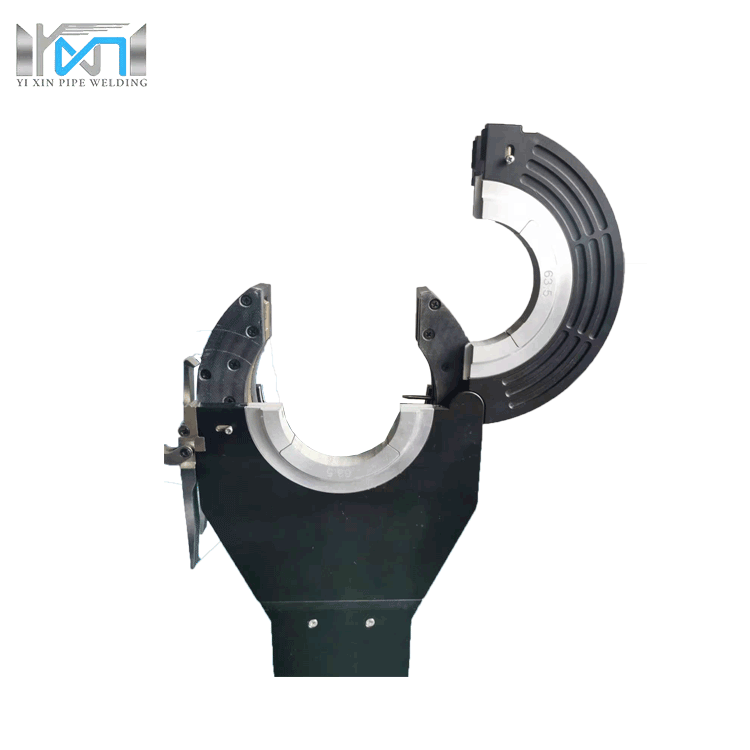

This automatic pipe welding machine (also known as automatic small pipe welding machine, closed type orbital welding machine, using GTAW welding process) is a special welding torch for all-position automatic tungsten arc welding (without welding wire) designed for butt joints of various pipe fittings. Fill the protective gas in the sealing cavity before welding to ensure that the welding seam is well protected. The gun body and the clamp body are air-cooled.

According to customer requirements, we can customize the compound fixture within the pipe diameter range. This fixture system can ensure the precise positioning of the welded parts without the need for positioning spot welding, so as to provide customers with high-efficiency and high-quality special welding guns. It can precisely realize all-position TIG tube/tube welding, with high reproducibility of welding results and ideal welding results.

This small tube automatic welding equipment is mainly used in tube to tube welding in electronics, instrumentation, pharmaceutical, engineering installation, military and nuclear power industries.

Technical Parameters

|

Model |

MT40 |

MT80 |

MT120 |

GT |

|

Pipe Diameter(mm) |

6-38.1 |

12.7-76.2 |

38-114 |

3-15.8 |

|

Rotating Speed(rpm) |

0.3-6 |

0.2-5.3 |

0.6-12 |

0.3-6.0 |

|

Protect Gas |

Ar |

Ar |

Ar |

Ar |

|

Cooling Way |

Water Cooling |

Water Cooling |

Water Cooling |

Water Cooling |

Device application:

Pipe diameter: 6-114mm (see the table above for different pipe diameter ranges)

Tube thickness: ≤3mm;

Tube material: stainless steel, carbon steel, titanium alloy, etc.;

Welding posture: all-position welding;

Welding form: butt, straight pipe and straight pipe, straight pipe and elbow, straight pipe and tee, etc.;

When welding carbon steel pipes, 5-8mm of the weld should be polished and derusted to expose the primary color of the metal;

The incision of the pipe should be flat, vertical and deburred, and there should be no gap after the two pipes are on top of each other, and the two pipes should be spot welded together;

Clean oil stains with acetone or alcohol

Product detail pictures:

Related Product Guide:

We usually continually offer you the most conscientious consumer services, along with the widest variety of designs and styles with finest materials. These initiatives include the availability of customized designs with speed and dispatch for OEM manufacturer Welding Source - Closed Type Small Pipe Welding Machine – Yixin , The product will supply to all over the world, such as: Bangladesh, Turkey, Jeddah, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.