With the construction, renewal, and transformation of urban municipal pipe networks, the amount of groundwater allocation projects has increased dramatically, ushering in a period of large-scale construction. At present, manual welding is still used on the site of large-scale water resource allocation projects. The matching accuracy is poor, the welding workload is large, the basic conditions of the pipeline are poor, the construction space inside the pipeline is small, the efficiency of manual welding is low, and the welding quality is difficult to guarantee. In addition, there is a lot of electrical equipment in the deep well, and the power supply is unstable, so the welding quality and welding efficiency cannot be effectively guaranteed.

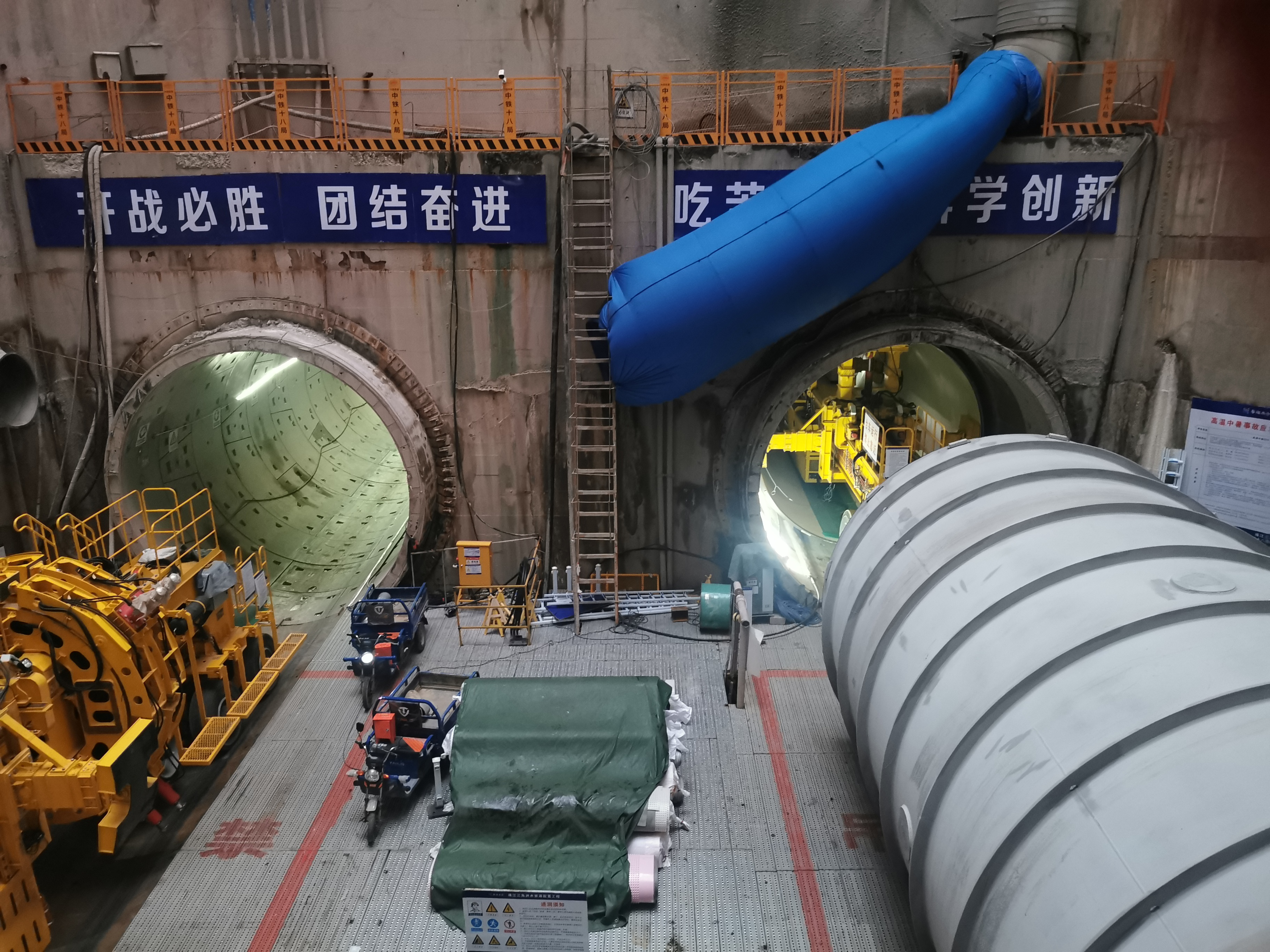

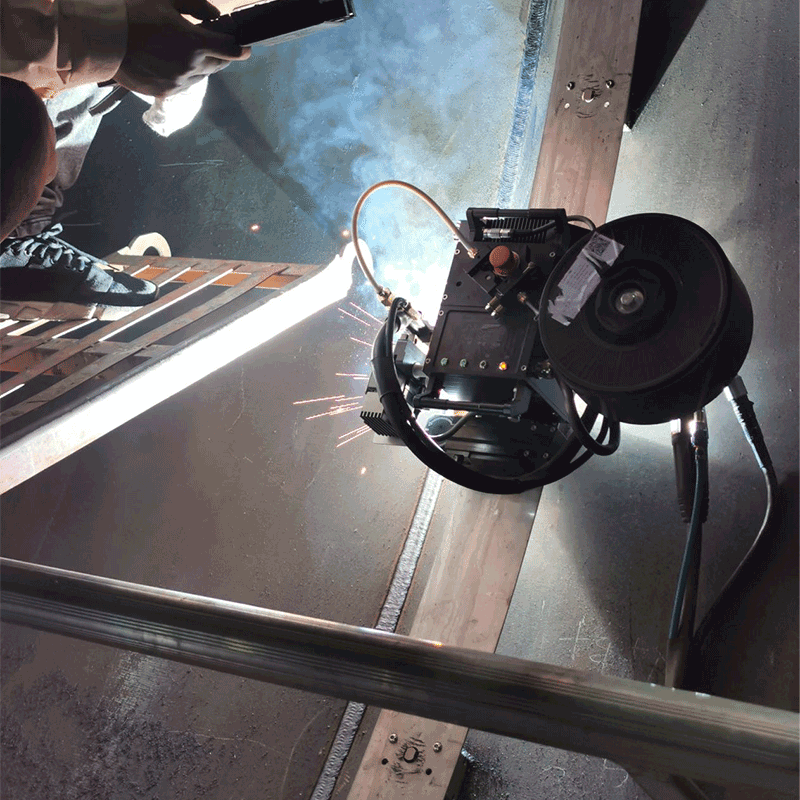

As mentioned above, the water resource allocation project is affected by the site conditions (4.8m super-large pipe diameter, underground construction, tough welding) and welding method (pure internal welding), resulting in pipeline laying efficiency that cannot meet the construction progress. Aiming at site conditions such as super large pipe diameter and only internal welding in water resource allocation projects, Tianjin Yixin designed and developed the corresponding pipeline all-position automatic welding system (also known as pipeline intelligent welding machine, portable pipeline intelligent welding equipment, orbital intelligent welding machine, pipeline automatic welding equipment, etc.). The system consists of an orbital all-position intelligent welding head, integrated wire feeding mechanism, WIFI communication programmable wireless remote control, intelligent welding system, customized welding power supply, special welding torch, a customized special track for internal welding, etc. After installing the track on the pipeline to be welded, install the welding head on the track. The welding head is geared along the track, and the welding torch is driven by the welding torch attitude adjustment mechanism to complete the welding operation according to the preset process parameters. The practical application proves that the equipment can realize continuous and stable welding, the welding pass rate is close to 100%, and the welding efficiency is more than three times that of manual welding. The use of automatic pipeline welding technology has greatly improved the efficiency of on-site pipeline construction, reduced labor intensity, and improved the overall quality of the project. It provides engineering application experience for the large-scale promotion of the pipeline automatic welding system in large-scale water resource allocation projects.

Post time: Dec-28-2022