Factory selling Orbital Pipe Welding Machine - YH-ZD-150 – Yixin

Factory selling Orbital Pipe Welding Machine - YH-ZD-150 – Yixin Detail:

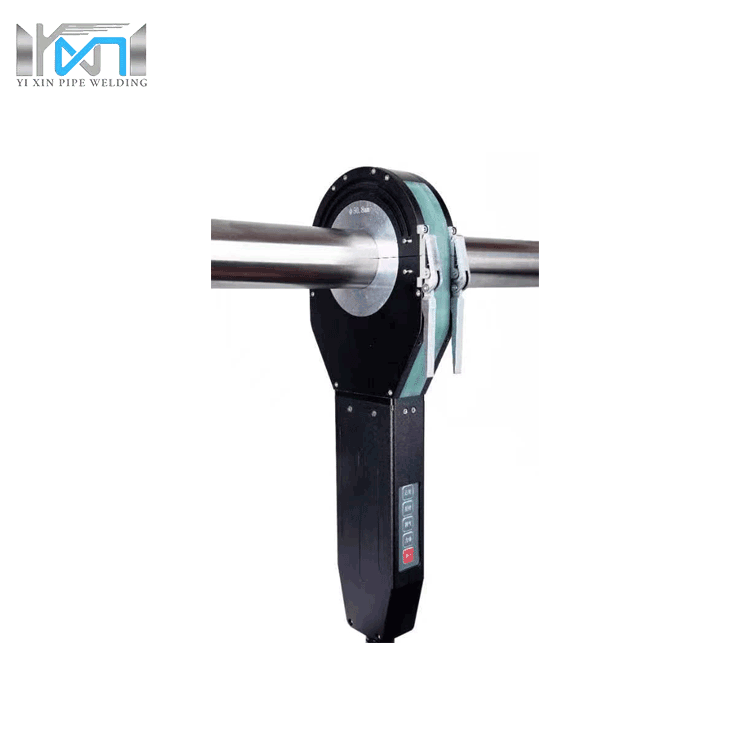

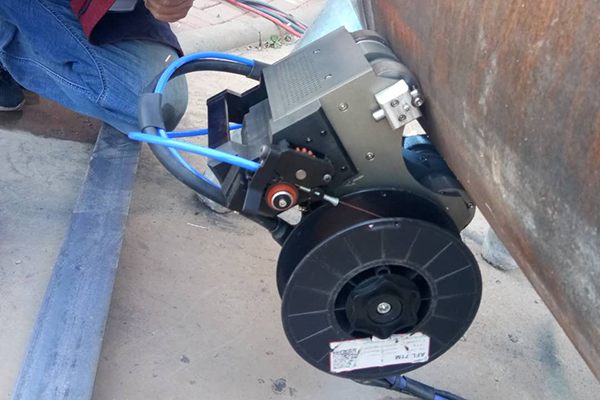

Magnetic All Position Automatic Pipeline TIG Welding Machine

YH-ZD-150 series Tungsten Inert Gas welding (TIG welding)machine is the main product of Tianjin Yixin Pipe Equipment Co., Ltd. It integrates a variety of cutting-edge automated welding technologies and is suitable for welding thin-walled tubes of carbon steel, stainless steel, titanium alloy and other materials.

TIG Automatic Welding Machine

Conventional manual argon arc welding is difficult to ensure its welding quality, while the all-position TIG welding machine has high welding quality and great welding shape, which can meet extremely high inspection standards.

In the welding process of TIG automatic welding, the welding current, welding voltage, wire feeding speed and other parameters that play a decisive role in the welding result are very stable. The welding quality is less affected by human factors, so the welding appearance is exquisite and the weld quality is high.

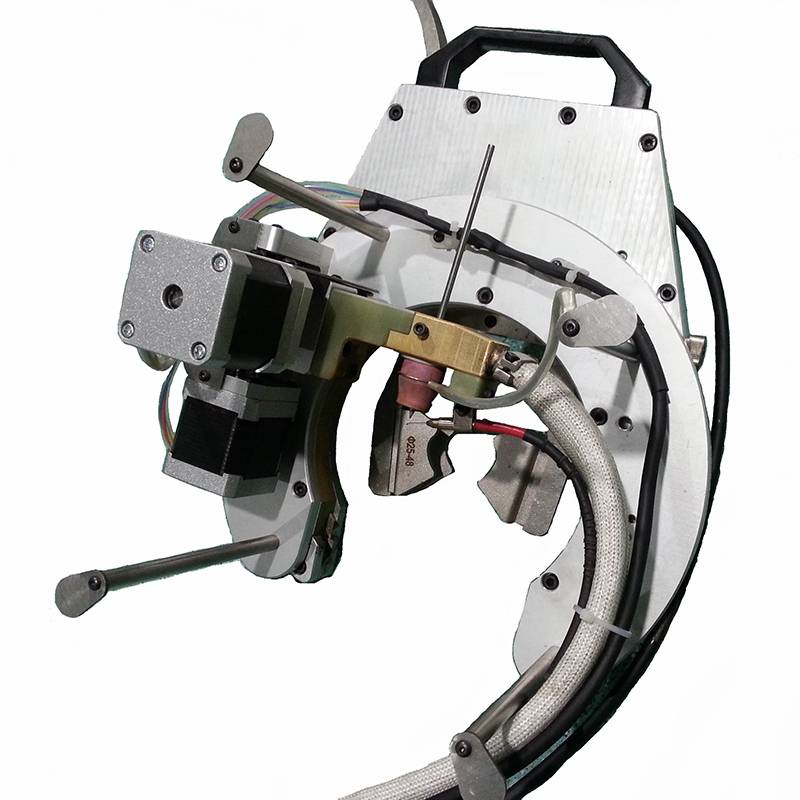

The self-developed TIG welding head is light and portable. The entire head uses aviation aluminum to make the body lightest to reduce the physical consumption of the constructors. The head is easy to install, convenient and fast.

Advantages of automatic TIG welding: great quality welding, strong fusion, high weld strength, beautiful appearance, no welding slag splash, etc.

TIG automatic welding fully shows the characteristics of high speed and high efficiency due to its high degree of automation. At the same time, due to the improvement of its welding speed, the time for internal argon filling is greatly reduced and the consumption of argon gas is saved.

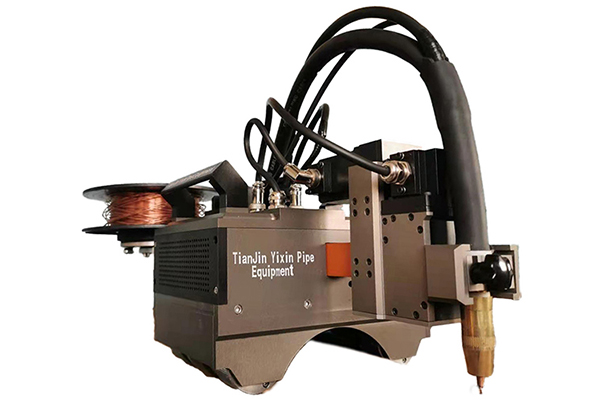

The basic configuration of YX-ZD-150 TIG welding equipment

• set of TIG welding head

• set of imported power control system

• piece of wireless remote control

• set of 10-20L water tank

Power control system

Adopting Japanese SanRex TIG welding power source, with novel AC VR function and optimized aluminum welding performance, 30 welding parameters storage function. The control panel is clear and easy to control.

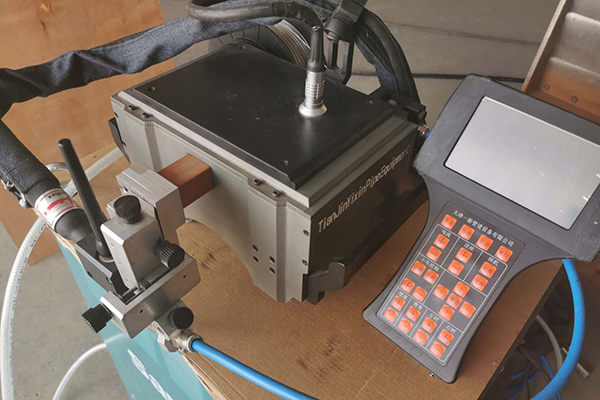

Multi-function remote controler

The high-definition color touch screen input process parameters can be clearly displayed in any environment. Through the touch screen remote control, the welding parameters such as height, left and right, swing width, walking speed, wire feed speed and arc length correction during welding can be realized through the touch screen remote control, with adjustment function and simple operation.

Technical Parameters:Automatic TIG Welding head

|

Parameters |

YH-ZD-150 |

|

head Size (L*W*H) |

400mm*360mm*300mm (with wire feeder) |

|

Weight |

14kg |

|

Horizontal working stroke |

60mm |

|

Swing Speed |

0-100 |

|

Wire Feeding Speed |

0-2m/min |

|

Walking Speed |

0-500mm/min |

|

Swing left and right dwell time |

0-1000ms adjustable |

|

Swing Width |

2-20mm |

|

Up and down stroke of welding gun |

40mm |

|

Wire Diameter |

1.0-1.2 Wire Feeder Diameter: 200mm 3 kilogram |

|

Applicable Materials |

Suitable for carbon steel, alloy steel, stainless steel, refractory metal aluminum and aluminum-magnesium alloy, copper and copper alloy, titanium and titanium alloy, etc., and can be welded in all directions. |

|

Applicable Pipe Diameter |

Above 125mm |

|

Applicable Pipe Thickness |

3mm-30mm |

|

Welding Way |

6 o’clock-12 o’clock, 12 o’clock-6 o’clock |

|

Applicable Groove |

V-shaped groove, double V-shaped groove |

Technical Parameters: Power Supply

|

Parameter |

SANARG 315APH |

SANARG 500APH |

|

Input Pressure |

Three-phase 380V±10% |

Three-phase 380V±10% |

|

Rated Input Capacity |

TIG 8.9KVA |

TIG 25.0KVA |

|

Rated Output Current |

TIG 315A |

TIG 500A |

|

No-load Voltage |

67.5V |

about 73V |

|

Rated Load Duration |

60% TIG 315A 100% TIG 244A-19v |

60% TIG 500A 100% TIG 387A |

|

Cooling Method |

Forced water cooling | Forced water cooling |

|

Protection Grade |

IP23 |

IP21S |

|

Insulation Class |

CLASS H |

CLASS H |

|

Size(mm) |

325*591*520(excluding rings) |

340*860*557(excluding rings) |

|

Net Weight(kg) |

44 |

80 |

Product detail pictures:

Related Product Guide:

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for Factory selling Orbital Pipe Welding Machine - YH-ZD-150 – Yixin , The product will supply to all over the world, such as: Armenia, Puerto Rico, Doha, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.