Factory Supply China 380V MIG Welder FCAW/GMAW with high efficiency

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Factory Supply China 380V MIG Welder FCAW/GMAW with high efficiency, We sincerely welcome consumers from both at home and overseas to come to negotiate company with us.

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for China Power MIG 1welder, MIG Welding Carbon Steel with Argon CO2, Many years of work experience, we now have realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question issues they do not understand. We break down those people barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Function:

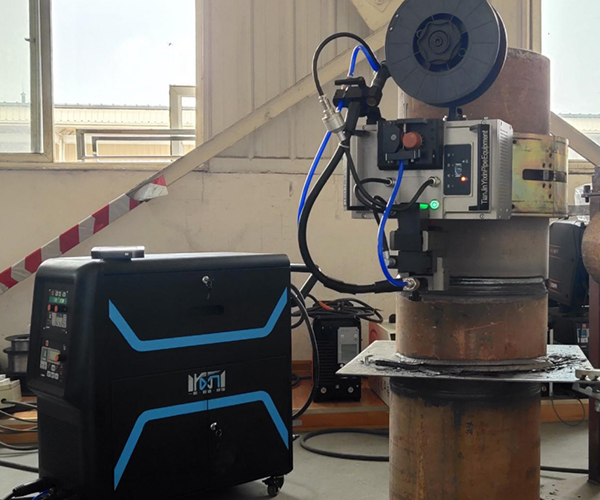

HW-ZD-200 series all position automatic pipeline welding machine is the latest masterpiece of the cooperation between Tianjin Yixin Pipe Equipment Co., Ltd. and Tsinghua University. It integrates more than ten patented technologies such as head automatic walking, electronic control system, and fault detection system. It can realize precise control of posture and time, intelligent gun swing function, even the ultra thick pipes can be welded with excellent welding quality. The maximum welding thickness can reach 100mm. It is a hot sale all position automatic welding machine in home and abroad,widely used in gas and natural oil pipe welding as first and great breakthrough. The whole system realizes integration optimization, adopts high-quality alloy steel shell of impact-resistant engineering, exclusive patented appearance design, exquisite and generous, compact and portable, and has a high degree of integration. All components can be integrated and stored in the outer box, which is convenient for on-site management and inter-project transportation; The base of the box is equipped with universal wheels, which is convenient for on-site movement and is suitable for various harsh welding environments.

Features:

◆Integrated welding head with wire feeder: compact structure, stable wire feeding, strong arc stability, light overall weight

◆Data record: Realize 360°24 welding zone parameter presets, automatic reuse, to meet the GMAW/FCAW-GS welding process of various working conditions.

◆Applicable: 5-100mm thickness pipelines. OD: above 125mm (for fitting and cap)

◆Welding material: Carbon steel, stainless steel, alloy steel, low temperature steel.

◆Portable use: Small size and light weight. The portable design is suitable for field construction operation requirements.

◆On site work: The pipe is fixed and the magnetic head is crawling on the pipe, which realizes the automatic welding of the pipeline in all positions

◆High quality: The weld seam is beautifully formed, and the weld seam quality can meet the flaw detection requirements.

◆High efficiency: Welding efficiency increased by 400% (compared to traditional manual welding)

◆Wireless control: Using a high-definition 5-inch color touch screen interface, which can realize real-time editing, input, storage and recall of welding parameters

◆Easy operation:Easy training, quick start, reducing dependence on scarce and highly skilled welders

◆Detection test: The weld quality meets UT/RT and other flaw detection tests.